Do you know the main structure of the automatic metal numerical control spinning machine and the installation characteristics of ta?

Release time:

2023-07-17

Do you know the main structure of the automatic metal numerical control spinning machine and the installation characteristics of ta?

CNC spinning machine is a large precision equipment, compared with other machine tools in the structure and performance are very different. CNC spinning machine is generally composed of core mold and spindle, rotary wheel and rotary wheel frame, device, tailstock and bed and other major components. Among them, the core mold and the spindle, the rotating wheel and the rotating wheel frame and the rotating wheel control device are called the three main structures of the CNC spinning machine. Compared with other machine tools, the internal structure is very compact, so in the installation also has other machine tools do not have the characteristics.

1. mandrel and spindle

Compared with the ordinary lathe, the rotating force of the CNC spinning machine is very large, especially the spindle part has to bear a very large radial force and axial force. In order to ensure the stability of the mandrel during installation, flanges and cones are usually used to assist in installation. At the same time, in order to facilitate the removal of the formed spinning part, a top part device will be installed on the spinning machine (a top rod is installed on the hollow main shaft, and the spinning part is pushed out from the core mold by the push of the hydraulic cylinder).

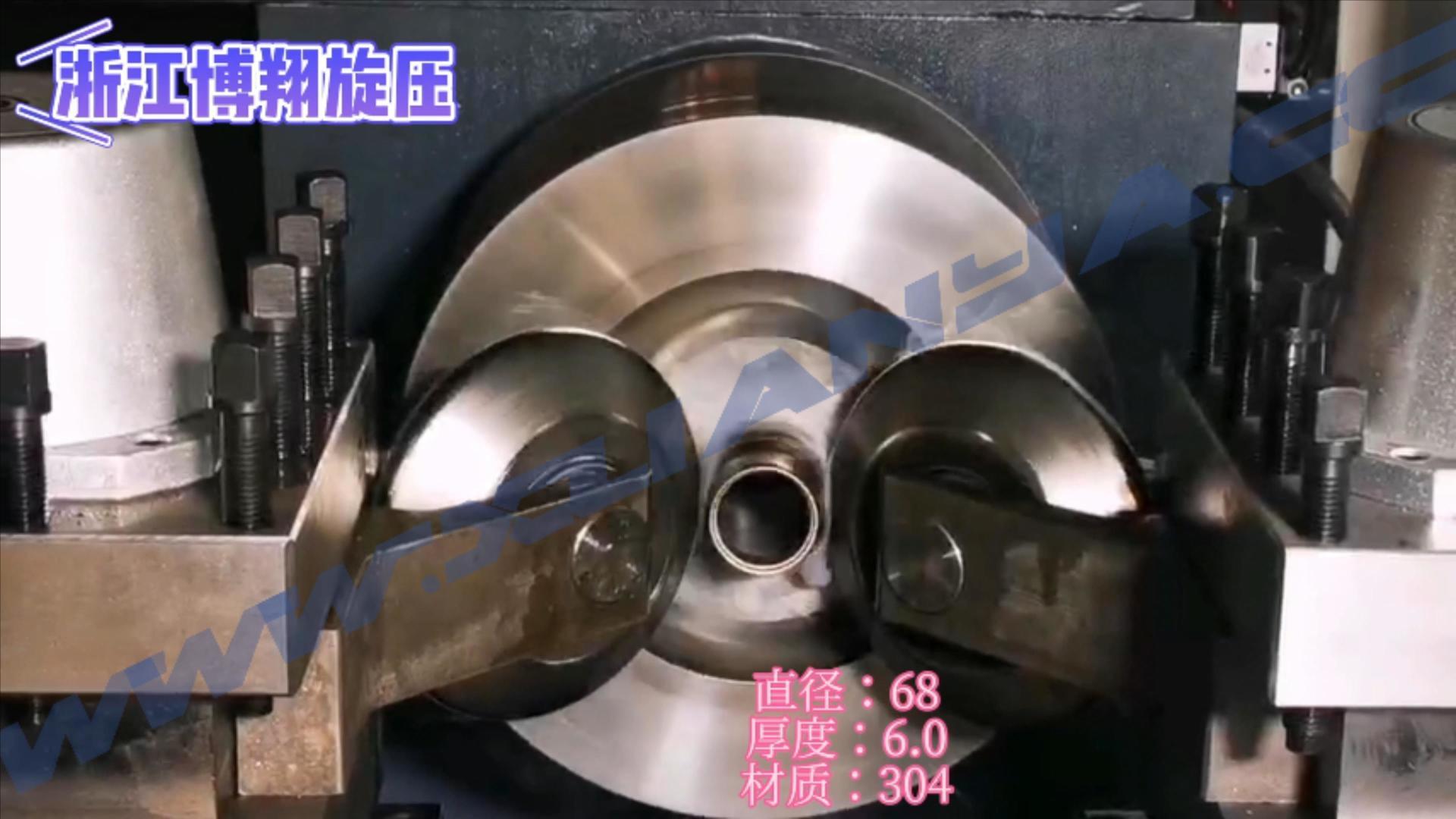

2. spinning wheel and spinning frame

The installation device of the spinning wheel and the spinning wheel frame is the obvious difference between the CNC spinning machine and the ordinary lathe in structure. The CNC spinning machine uses an axial fixing method to fix the spinning wheel on the spinning wheel arm, and then the spinning wheel arm is installed on the spinning wheel frame. Sometimes, in order to improve production efficiency, two rotating wheels are directly connected in series, but the installation position behind is not changed, which is very suitable for mass production.

2. spinning wheel and spinning frame

The installation device of the spinning wheel and the spinning wheel frame is the obvious difference between the CNC spinning machine and the ordinary lathe in structure. The CNC spinning machine uses an axial fixing method to fix the spinning wheel on the spinning wheel arm, and then the spinning wheel arm is installed on the spinning wheel frame. Sometimes, in order to improve production efficiency, two rotating wheels are directly connected in series, but the installation position behind is not changed, which is very suitable for mass production.

3. wheel control device

In addition to manual spinning, the control of the spinning wheel is generally achieved by means of a profiling device. This device through the use of hydraulic servo valve and electro-hydraulic servo valve, to achieve multiple cycle copy spinning. The movable template controls the movement of the shape arrestor by rotating slowly, and then controls the movement of the linked spinning wheel until the spinning wheel moves the same as the predetermined template. The movable template can perform translational movement and rotational movement, even continuous movement and periodic intermittent movement can be completed, and the corresponding movement mode can be selected according to the shape and material of the actual workpiece.

In addition to these three main parts, in order to fully play the function of the equipment and meet the specific requirements of specific workpieces, the CNC spinning machine can also be equipped with related auxiliary facilities. For example, the centering mechanism of the installation card workpiece, the cutting edge of the workpiece, the hemming device and so on. If you want to prevent the sheet from wrinkling during deep drawing and spinning, you can also equip a reverse roller to gradually deform the sheet. Usually, a complex shape of the workpiece from the sheet metal installation and positioning and spinning forming, and then to the completion of the necessary auxiliary processes, until the workpiece removal of the whole process can be controlled in sequence. However, the CNC spinning machine adopts CNC programming control, which can easily change the process sequence and make the production more flexible.

Related News