How to maintain the CNC spinning machine

Release time:

2023-08-08

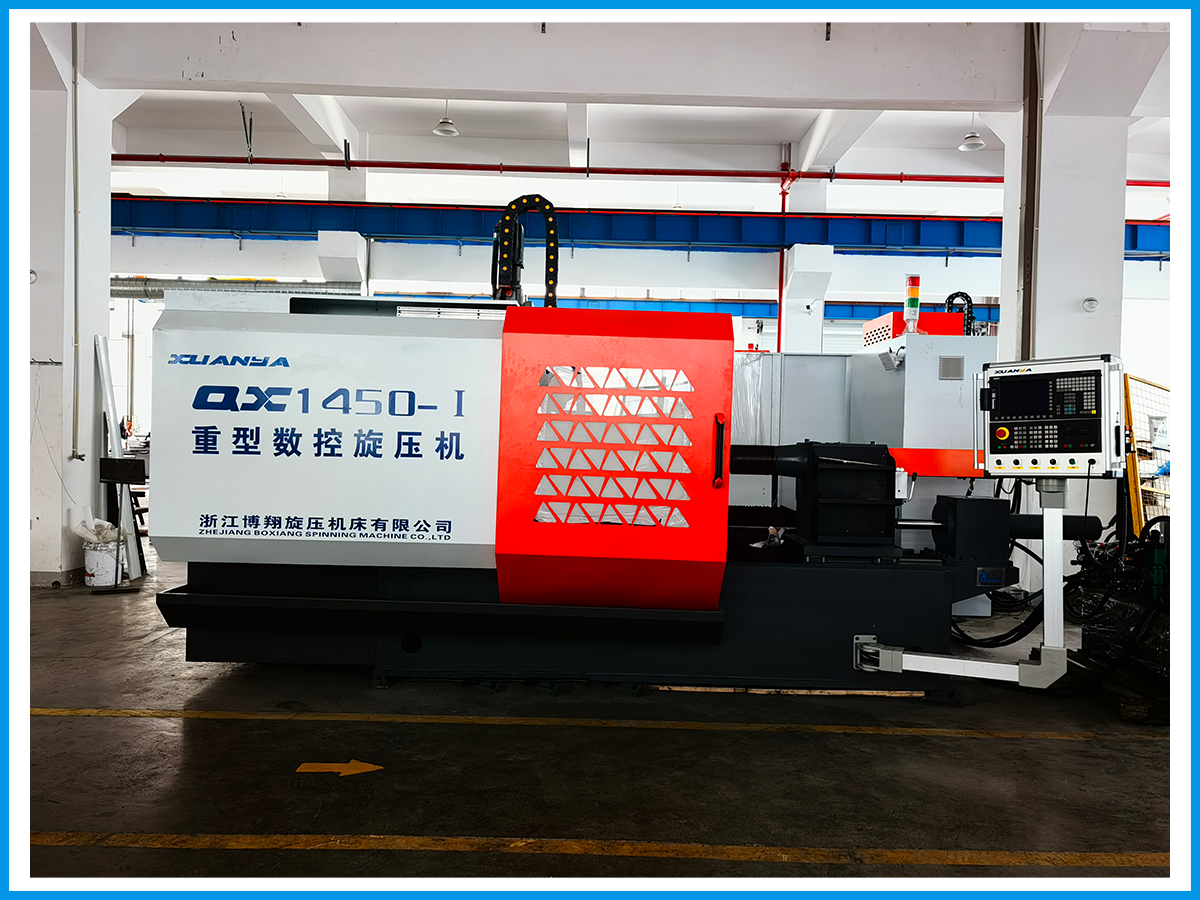

How to maintain the CNC spinning machine

CNC Spinning MachineIs a kind of precision equipment, if the operation is improper, it will affect the service life and processing accuracy of the spinning machine. Therefore, the operator of the CNC spinning machine should not only be familiar with the procedures for processing various materials, but also be familiar with the maintenance knowledge of the equipment. Good maintenance is not only beneficial to the later operation, but also can effectively extend the service life of the equipment.

How to maintain the CNC spinning machine and extend the service life of the machine? Generally speaking, the following points need to be done:

1Select the appropriate use of the environment CNC spinning machine contains high precision components, so to stay away from the vibration amplitude of the machine, such as punching, forging equipment, etc.; in addition to avoid direct sunlight and other thermal radiation, to prevent the explosion of oil inside the machine. In addition, too wet, too much dust or corrosive gas places are not suitable for placement of CNC spinning machine;

2To ensure a stable power supply, in order to prevent the power supply from fluctuating greatly (± 10%) or generating instantaneous interference signals, it is recommendedCNC Spinning MachineThe power supply for the exclusive (such as from the distribution room dedicated to a line for CNC machine tools to use alone) or the use of voltage regulator devices, to a certain extent, can reduce the impact of power supply quality and electrical interference on CNC machining;

3During the work, the air in the mechanical processing workshop often contains oil mist, dust and other impurities. If it falls into the circuit board or other electrical components of the numerical control system, it is easy to cause the insulation resistance of the components to drop, resulting in damage to the circuit board or electrical components;

4Formulate effective operation specification for numerical controlSpinning machineA series of practical and effective operating specifications should be drawn up. For example, smooth, maintenance, reasonable use and shift change must draw up standard work flow, requiring operators to strictly implement and make corresponding records. The development and compliance with the operating process is an important prerequisite for the safe operation of CNC machine tools. Practice has proved that many production problems can be reduced or avoided through standardized operating procedures;

5The numerical control spinning machine should not be sealed for a long time without starting up for a long time. The numerical control spinning machine should also be powered on and run regularly. Xiao Bian recommends electrifying 1 to 2 times a week, each time about 1 hour of idle running, through the heat generated during the operation of the machine to reduce the humidity in the machine, so that the electronic components do not keep dry. At the same time, timing power can also find out whether the battery still has electricity. If there is insufficient power, it can be charged in time to prevent the loss of system setting parameters.

The longer the service life of the CNC spinning machine, the more benefits it can generate for the enterprise. Therefore attach importance to numerical controlSpinning machineThe maintenance of the spinning machine is the premise to give full play to the function.

Related News