Spinning process

Spinning-step forming:

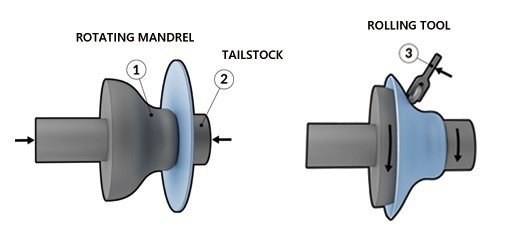

When using the spinning process, the disc blank is tightly fixed between the spinning machine core die and the tail top. The key point is that the internal shape of the spinning machine core die and the workpiece is consistent, and the spindle drives the blank to rotate.

By the rotary wheel from the longitudinal and axial control to the blank to apply extrusion pressure, so that the material is gradually extruded to the core die, while the rotary wheel alternately to the edge of the blank reciprocating curved movement, the final finishing movement to make the workpiece to achieve the desired size and surface quality.

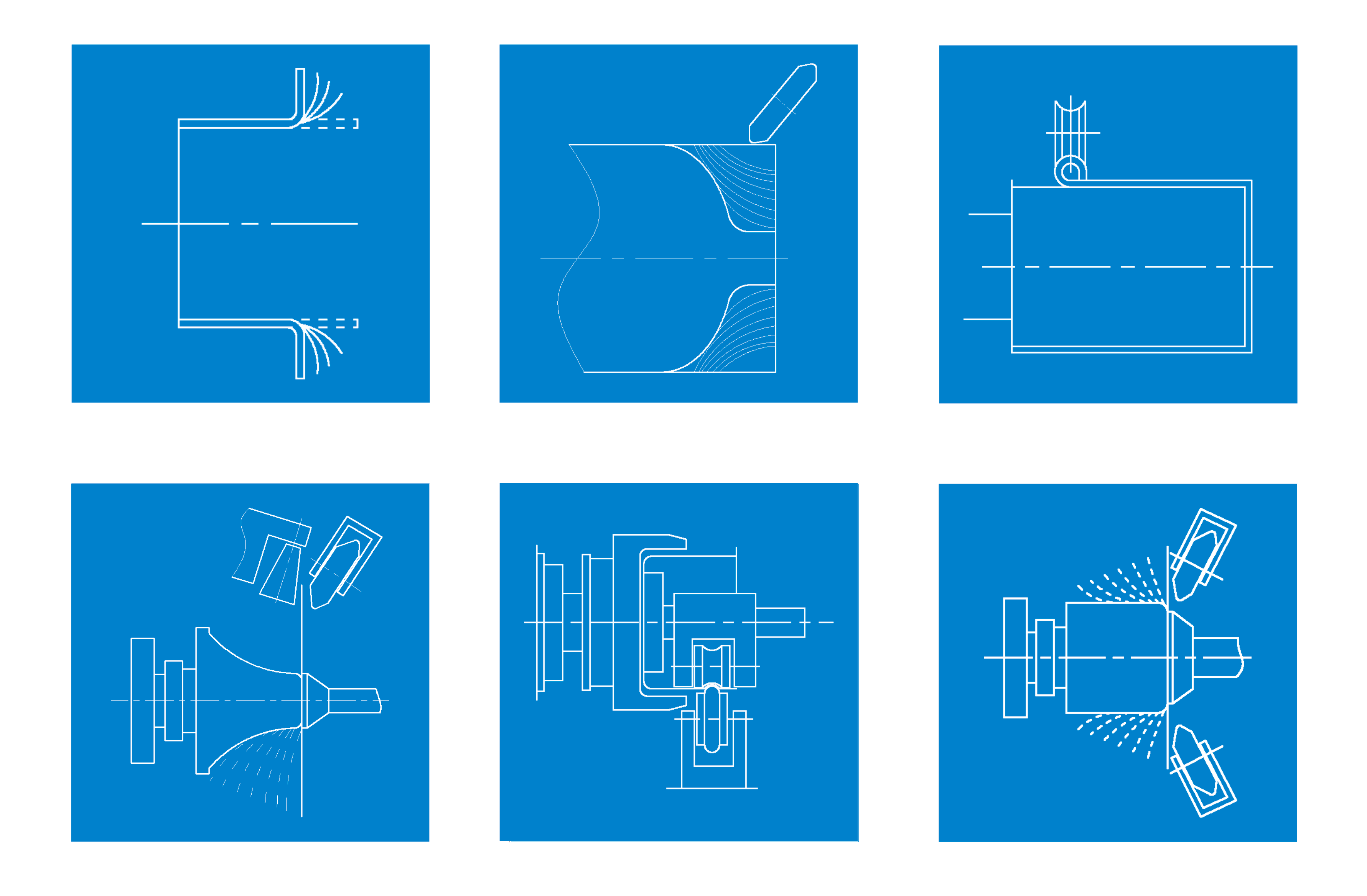

principle of spinning process:

In the process of spinning, which is a chip-free forming process, a metal disc blank, a simple blank or a preform is first put into rotation. The metal piece is pressed by the spinning wheel and the metal starts to flow. In this way, complex bus bar shapes can be obtained with minimal tooling costs. The tolerance range is extremely small, and the surface quality is excellent for various hollow bodies. The advantages of the spinning process are obvious: with this process, the wall thickness and contour of the workpiece can be determined with maximum accuracy and can be accurately repeated.

Contact Us

Company address: No.1 Xinqi Road, Xiage Town, Xianju, Taizhou City, Zhejiang Province

Address of R & D Center: No. 500, Zhongcun Industrial Park, Binhai Town, Wenling City, Taizhou City, Zhejiang Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.