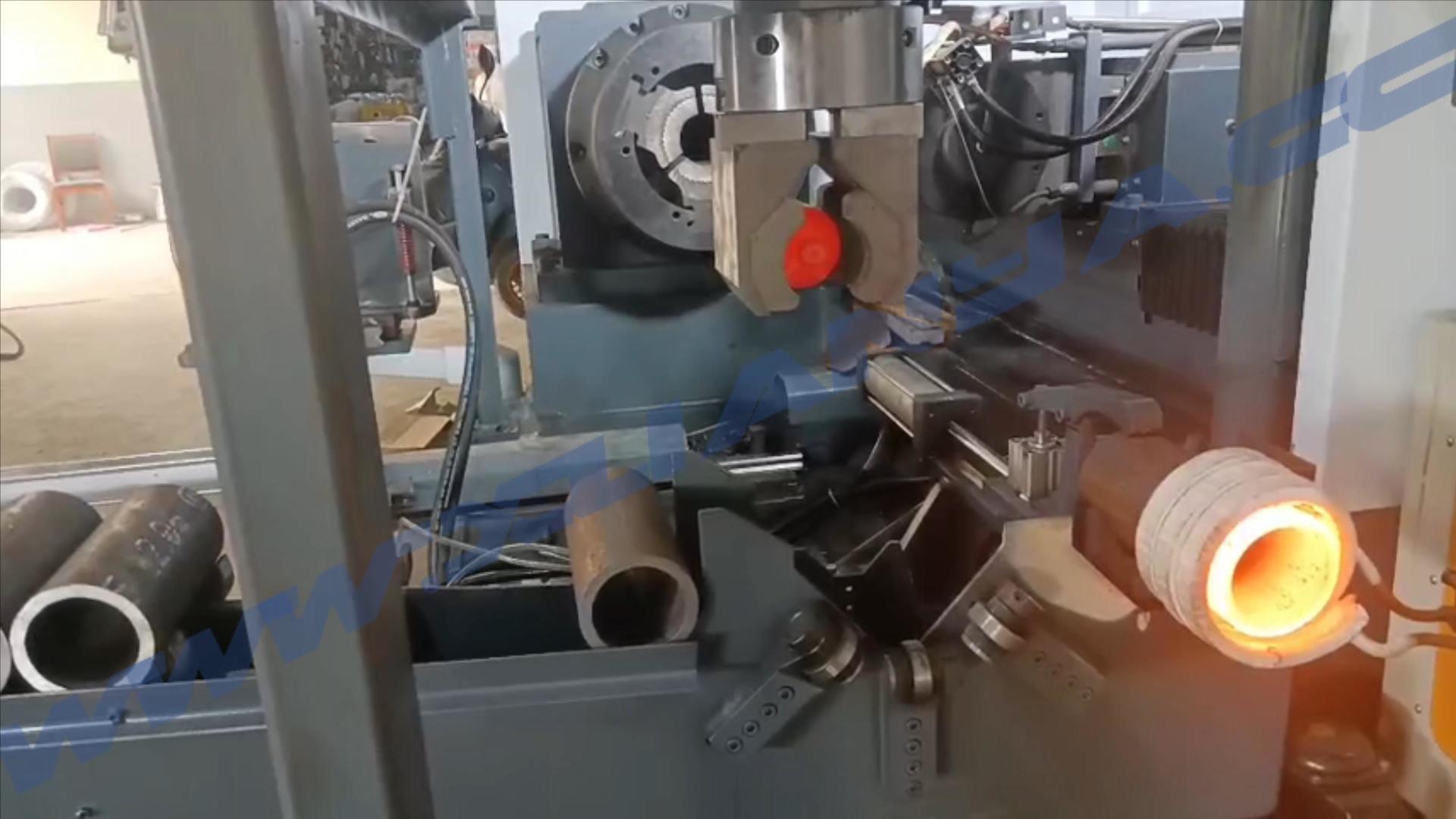

Perfect cooperation of automatic mechanical arm in spinning CNC machine tool

Release time:

2023-06-03

Perfect cooperation of automatic mechanical arm in spinning CNC machine tool

With the use of CNC spinning processing more and more widely, now many products in the market are selected CNC spinning machine into production. For example, the main processing materials in the lighting industry are aluminum and iron, and the production is relatively stable. Therefore, many manufacturers want to replace labor with machine automation to reduce labor costs. Is it appropriate for the CNC spinning machine to be put into automation? Whether the production line put into automation is very stable has become the focus of attention.

Numerical control spinning machine processing is originally a fully automatic processing process controlled by numerical control program, and most of the automation transformation is operated by manipulator in the feeding and blanking links. The stability of the manipulator operation is related to the following two factors.

The way and strength of 1. manipulator clamping product demoulding

Because the spinning product needs a certain demoulding force after molding, especially the barrel-shaped product, the selection of the clamping method and strength of the manipulator is the key to the smooth demoulding of the product. If the strength is too large, the aluminum products will be easily deformed or scratched. If the strength is too small, the product will not be successfully removed from the mold or will be damaged by falling halfway.

2. the Production Stability of NC Spinning

After the CNC spinning machine is produced for a long time, the temperature of the mold and the rotating wheel will rise, which will affect the size of the demolding force. In addition, the production process occasionally due to material or other factors of product fracture phenomenon, fracture after the manipulator is effective clamping is also need to consider the problem. If the manipulator cannot smoothly demold the product from the mold and continue to feed, the next product spinning will increase the force on the cutter wheel due to the blank on the mold not being cleared, and the material sheet, cutter wheel and mold will heat up sharply, thus normal production cannot be resumed.

Although the stability of the automation of the CNC spinning machine for mass production still needs to be further improved, it does not mean that automation is not feasible. Manufacturers in the CNC spinning customization, in the design stage can be done in advance of the automation design. After the newly purchased CNC spinning machine arrives at the factory, it can not be directly put into automated production. After a period of trial production, the CNC spinning machine will be upgraded automatically after the production situation is stable, so as to achieve the purpose of reducing costs and increasing efficiency.

Related News