Several Common Problems of NC Power Spinning

Release time:

2023-08-19

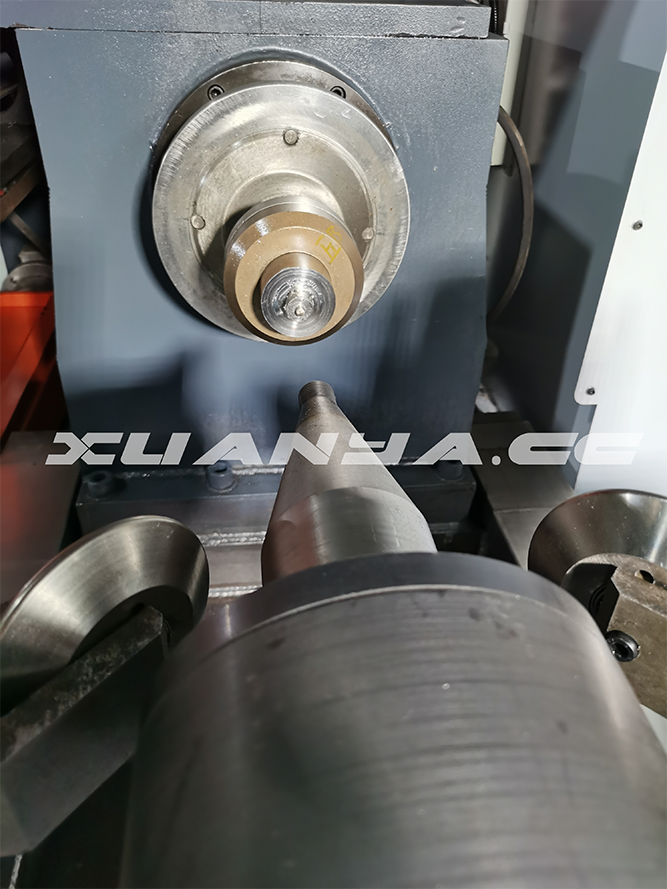

CNCpower spinningAlso known as shear spinning, its thinning rate is greater than that of ordinary spinning. Ordinary spinning is mainly tensile thinning, and strong spinning is shear thinning. Power spinning requires a greater spin pressure, so the problems encountered by power spinning are more likely to be reflected.

Fracture of 1. spinning wheel mandrel under insufficient stress

The spinning mandrel is an essential accessory for assembling the spinning wheel. In addition to allowing the wheel to rotate, it also bears the force of the wheel. When the metal material to be spun is very thick, the spinning mandrel is prone to fracture due to an too large shear force. In order to improve the force capacity of the spinning mandrel, we can start from two aspects: first, increase the diameter of the mandrel, and second, quench and temper the mandrel instead of quenching. In order to increase the wear resistance of the mandrel, some companies have quenched the mandrel, so the mandrel is easy to break.

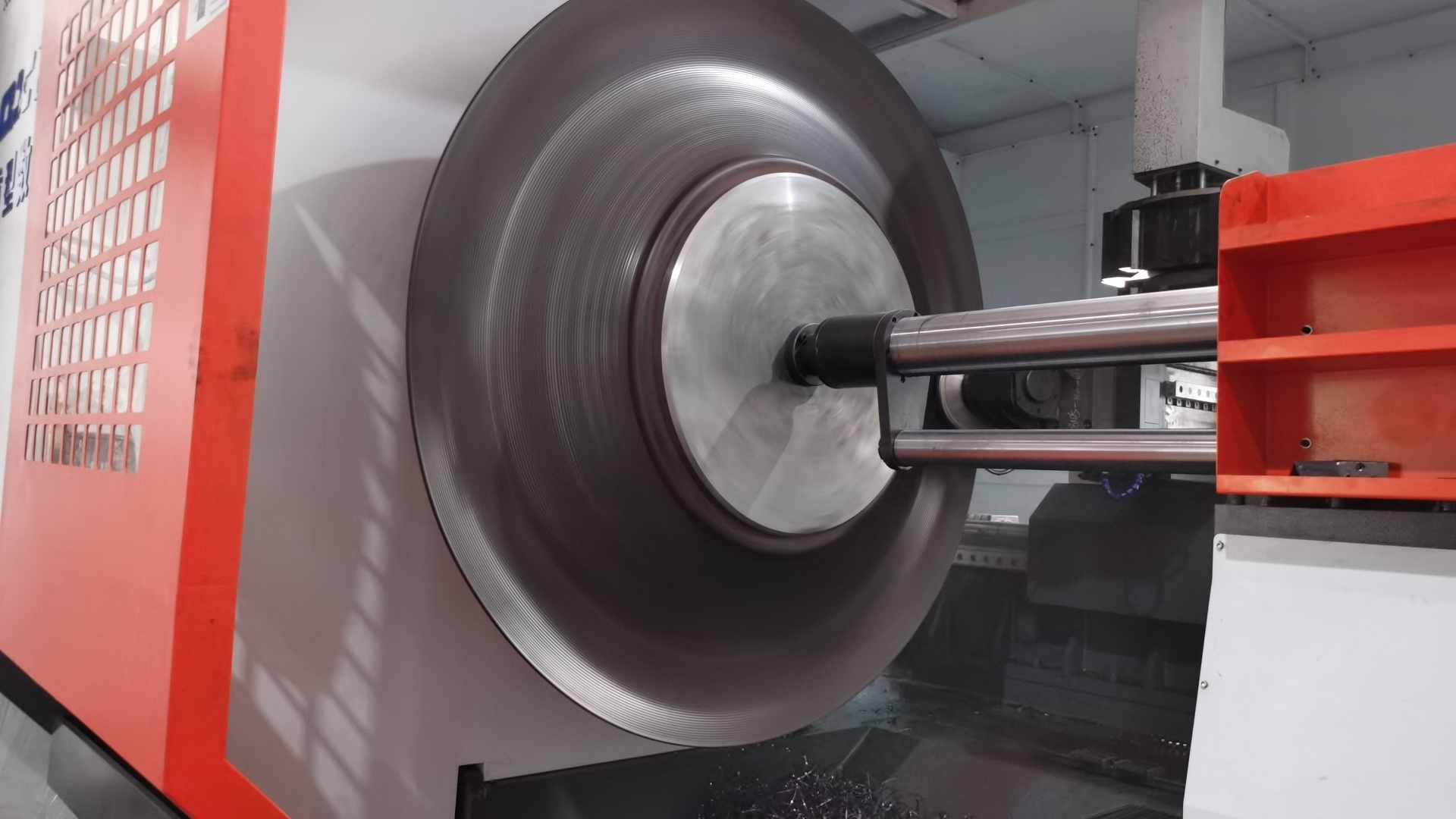

2. the process of strong rotation, the speed of the large mold is reduced or suddenly stopped.

power spinningIn the process, if the large mold has a slow down or a sudden stop, the torque of the spindle is generally not enough, and the following measures can be taken:

First, you can check whether the spindle belt is loose or slipping, which can be solved by adjusting the belt preload;

Second, decelerate and increase torque, replace the size ratio of the pulley to achieve the deceleration effect, or add a reduction gear, the principle is the same;

Third, replace a larger motor, but the cost of this method will be higher.

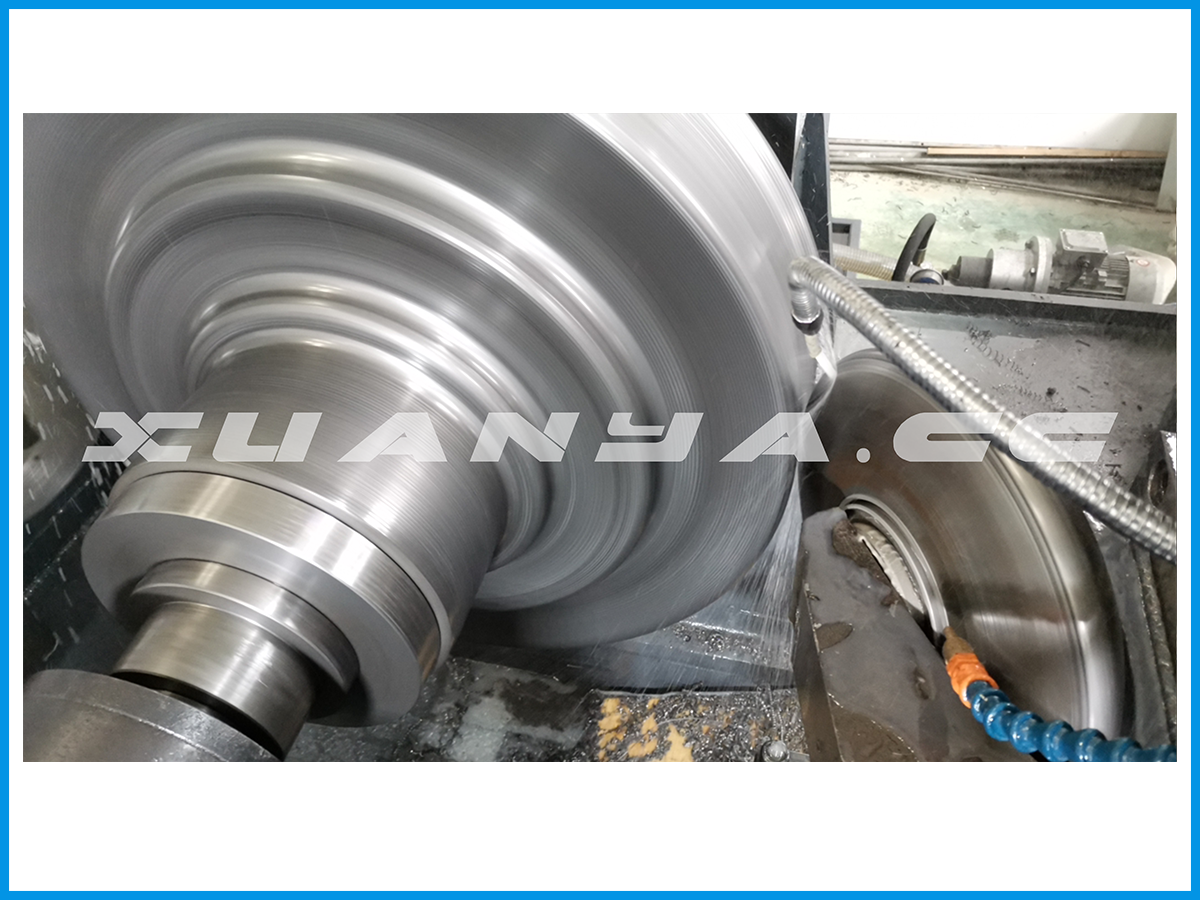

Material withdrawal occurs during strong 3. rotation

The phenomenon of material withdrawal is easy to appear in the process of strong rotation, especially some products with taper. When the gap between the rotating wheel and the mold is too tight, the product will be returned to the height of the product. In addition, there may be vibration of the machine tool. The surface of the spinning product will produce some spiral-like texture, which is different from the normal uniform spinning grain. At this time, the gap between the spinning wheel and the mold needs to be enlarged.

4. system alarm during strong rotation

In this case, the thrust of the lead screw is generally not enough, the rigidity of the CNC spinning machine will decrease after long-term operation, and the spinning wheel will let the knife in the spinning process. Do CNC powerful spinning products to buy the right spinning machine is more important, in order to long-term stable production.

power spinningIt is a commonly used processing method in metal spinning processing, which is often used to process some difficult-to-deform materials and has a wide range of applications in aerospace manufacturing. For the problems in the process of power spinning, experienced technicians or operators can quickly find the crux of the problem, solve the problem in time, and reduce the impact on production.

Related News